3D Creations in 3D Space.

Sculpting Full-Size 3D Digital Models with TRUE HUMAN PERSPECTIVE, at last!

Work in true 3D space and feel the model’s presence.

(Honestly, it’s hard to believe it’s not really there!)

If you’ve not experienced VR creation yet, let us know we’d love to introduce you to it. When you can actually reach out and move control points on a virtual model that is unquestionably sitting there in the room in front of you, then you get it. There is a palpable shock that many experience upon removing the headset to find that the vehicle that was just right there in front of them, has disappeared. “Who stole the model??”

Consumers are human, and they only see products when they’re finished, at full size. VR technology now provides the means to develop products digitally at this human scale, in real 3D space. It projects into your field of view a vehicle that is accurately represented in scale, perspective, depth and surface finish… can you really afford not to use it? This is a tool for design studios that value innovation, design quality, process efficiency and saving money.

Turbocharged Design Iteration.

Ultimate design freedom.

Try many ideas. Fail fast, and move on.

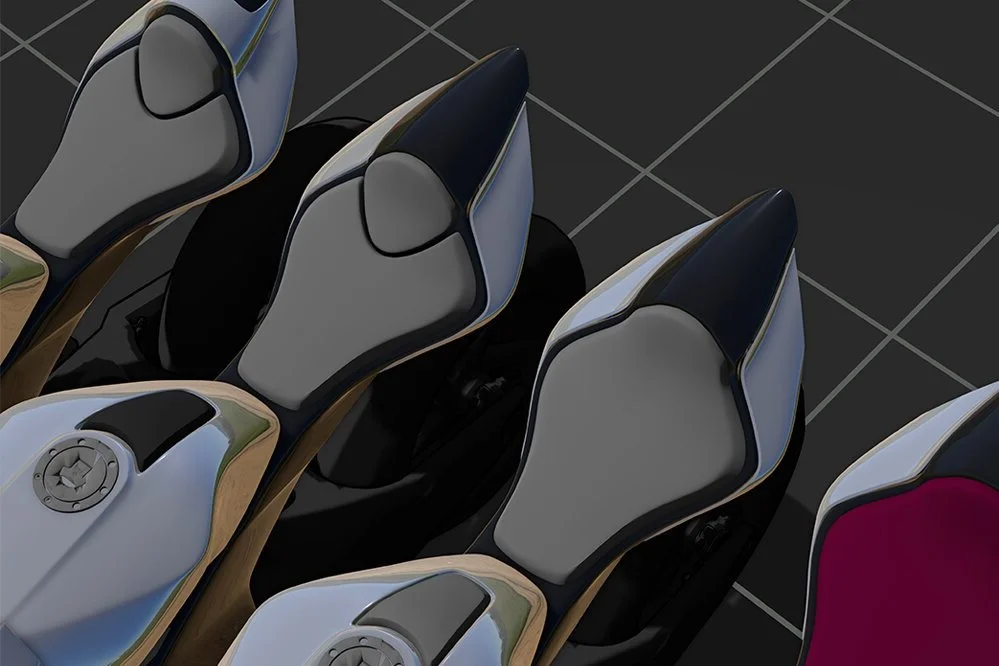

The job of industrial design is all about ideas, iteration and refinement. Trying different ideas and pushing boundaries is easy and fast in VR. With the ability to compare several solutions next to one another at 1:1 scale it’s easy to make good decisions to proceed.

Traditional Skills.

Next Generation Tools.

Clay modellers with a vision for the future are now hand crafting digitally, using VR.

Put your concept development back in the hands of 3D experience.

With the steady decline of clay opportunities, VR offers a new opportunity for skilled clay modellers to deploy their skills digitally, in a medium that has a future.

It’s a common sentiment that we need to be able to physically touch the model in order to fully understand it. Touch is certainly a nice-to-have if your model is matt brown and not giving comprehensive feedback of it’s form through reflected light… Honestly, I’ve never seen all the people running their hands all over vehicles at shows… mostly they just stand back and look. Anyway, we think you should mill a clay for verification, and at this point we can refining surfaces here and there by millimeters, not centimeters.

Maximum Efficiency.

Forget Labour Intensive Workflows.

Sculpt Digitally, then Mill with Confidence.

Milling a clay model is relatively expensive. It also takes expensive infrastructure that needs maintenance, and it takes a lot of time and energy to build up, to mill and to manually clean up the model.

This jumping from 2D creation, into 3D clay review and back into 2D rinse-and-repeat can be avoided by keeping the development in 3D for the entire creation and review process.

Collaborate Remotely.

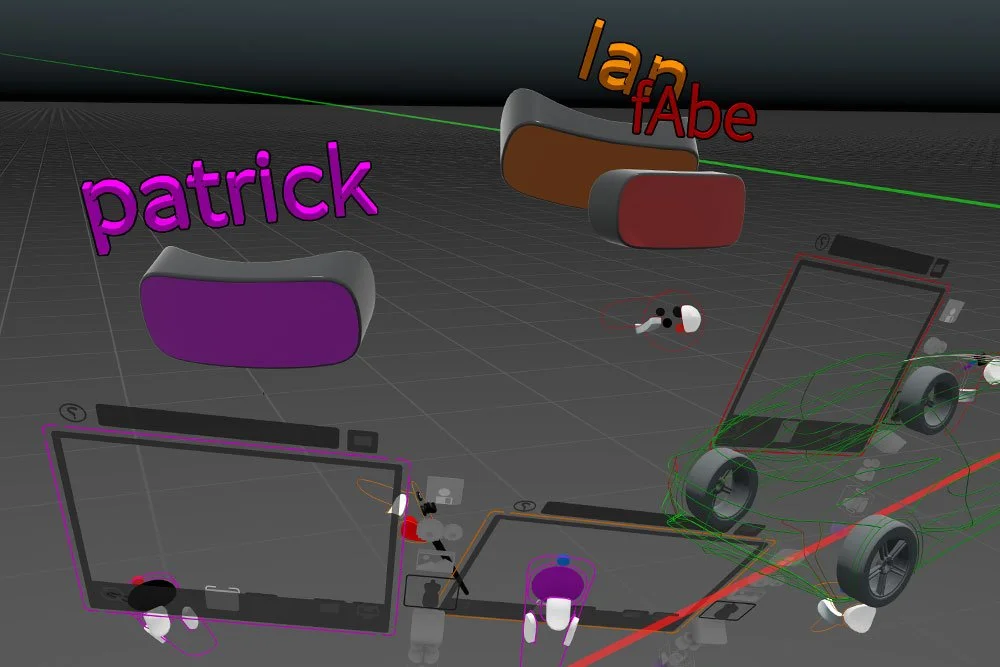

Meet your Team Around a Virtual 3D Model from anywhere.

Access the world’s best talent.

Connect to your team and project the model and your teams’ avatars into your immediate surroundings, from anywhere with an internet connection.

Physical location is no longer a consideration in freelancer selection, meaning studios can access the the best talent for their project. We have the talent if you have the project.

From Nick Graveley’s own personal experience, after a career working on-site internationally and trying to balance a home life, it’s been a revelation to not have to travel away to work on-site at a client’s clay facility every week. Now he works from home and sees his wife and kids every day… so it’s a double edged sword.

“What has been see cannot be unseen! It’s just incredible! It feels like we are there together, you know, exactly like before around the clay models that we were working on together. I mean, really, it's just mind-blowing!”

Fabien Rougemont

(Redster Design)

Environmentally conscious.

Cut material waste.

Cut physical travel.

Milling a clay model creates a lot of waste, which is both expensive and environmentally damaging if not recycled.

Mostly it ends up as land-fill.

Travel to a central location is no longer necessary making coordination much easier, and less travel means less pollution.

Make Informed Decisions for Faster Design Development.

Speed to Market.

Seamless communication between Design, Engineering, and other stakeholders.

When you create in the same environment as you review, you can very quickly pull 3D sketch lines and surfaces around to understand how to evolve and idea. Better feedback makes better decisions.

When the barriers between departments are reduced, we can collaborate much more effectively. Engineers and designers getting together around a virtual concept model with imported package data, have clear information in front of them to fuel discussion. Being able to zoom in and actually go inside the model, focus on a detail and make 3D sketch lines, collaborators are able to quickly understand issues and convey possible solutions.

Secure.

Work Offline alone, or Collaborate with others in a Secure VR Studio using “Collab”.

Gravity Sketch “Collab” Runs on Certified Data Servers (ISO27001, TISAX & DCSO).

Security is a big concern for anyone developing a product. As experienced clay modellers we’ve always had to work behind closed doors. We take data security very seriously, and our chosen software Gravity Sketch is fully certified secure.

That means, when you go into a Collab room with your colleagues that’s a private space and package data that is uploaded or created in that VR space is secured against data breach, and access control is managed by the account owner through the Landing Pad browser interface.

Cost Savings.

Save Time & Save Money whilst Increasing Quality.

Reduced facility costs. Reduced labour costs. Reduced Material costs

“In the design phase there is the potential to save seven months, as premium OEMs typically spend 13 months on this phase today versus six months for the best-in-class challenger.

Smart digitalization can save up to a year of development time and 20 percent of R&D costs.”

(Kearney, Jan ‘23)

If you want to know more in detail about the details of how automotive product development processes are today and how integrating VR modelling provides benefits, then this video is for you.